ADDITIVES

- Fricmart’s 4th Generation Formula Technology is based on the mechanism known as T3B – Tribological 3rd Body

- The formation of Micro structural Transfer Film or Friction Layer on the interface of friction partners (i.e. Brake pad and Rotor) is known as Tribological 3rd Body ( T3B).

- T3B is chemically a Solid-Fluid mixture formed during translation of Kinetic Energy due to combined effect of Thermo-chemical & Plastic Deformation of friction partners.

- The micro mechanical structure and properties of T3B plays important role in identifying squeal and judder due to the phenomenon called `stick-slip’.

- Fricmart achieved this by using unique speciality Additive PG-902®

Fricmart’s Additive PG-902 is made in-house with unique blend of Polarized Graphite that not only posses good Lubricity but also exhibits extremely good load bearing ability and Anti Wear performance.

Unlike conventional additives, PG-902 additive releases Electrically charged Micro Flakes with alternating +’ve and ─’ve charges to form a continuous micro film /layer across the rotor/drum surface during `wearing-in’.

This Micro Film of `like molecules’ acts as physical separation between opposing surfaces ie. Brake pad & Rotor, protects the braking path from any damage and maintains consistent friction till last residual layer of Lining.

There is neither a Sulfur effect ( due to stress corrosion ) nor Reaction products’ effect ( formation of hard matrix ) when Additive PG-902 plays the Major role as Tribological 3rd Body (T3B).

Fricmart’s POLAR GRAPHITE ADDITIVE PG-902

- Helps in building special formation of `T3B’ layer, a Protective Thin Transfer Film, Micro structurally tough with excellent adhesion to the metal surface.

- Builds strong and durable “Cohesive Bonds” due to excellent `Visco- Elastic’ property.

Illustration of Tribological 3rd Body (T3B)

Significance of ‘T3B’

- Because of long life of Transfer film, no new layer need to be formed very often from the friction composite. This resulted in `low wear’ of Pad / Lining.

- Excellent `adhesion’ of Transfer film to the mating surface contributes to less wear of mating surface and thus protects rotor /drum against deformity resulting from heat spots ,scoring , warping , ovality etc.

- Stabilizes friction because of `common origin’ and `like molecules’ between transfer layer & friction partners thus minimizes variation between Static and Dynamic coeff. of friction – µ to minimize `Stick- Slip’.( however a thick patch of transfer film is NOT preferable as it may cause judder )

- The quality of friction layer and transfer layer is responsible for stable friction, braking comfort (NVH ) and wear life of friction partners.

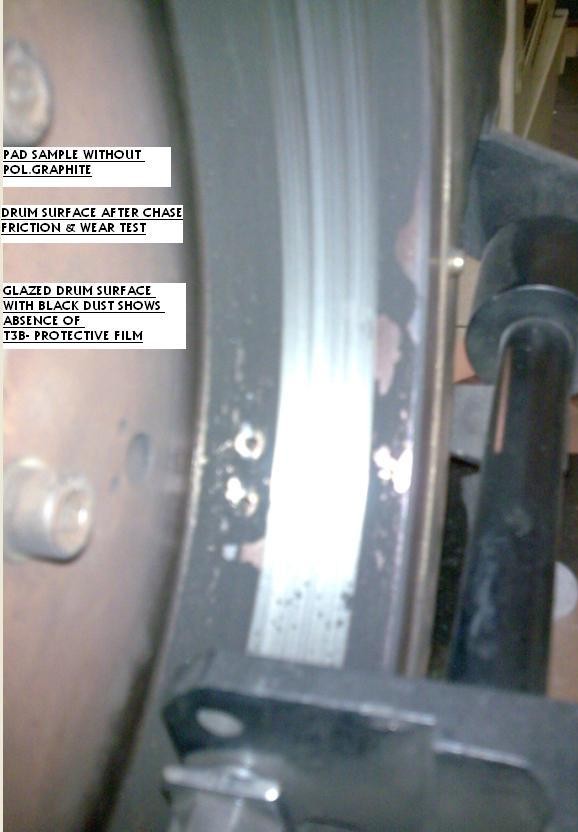

Brake Drum after ‘SAE J-661’ Friction & Wear Test

Drum without T3B Layer

GLAZY DRUM WITH BLACK DUST

Drum with T3B Layer

MATT DRUM NO BLACK DUST

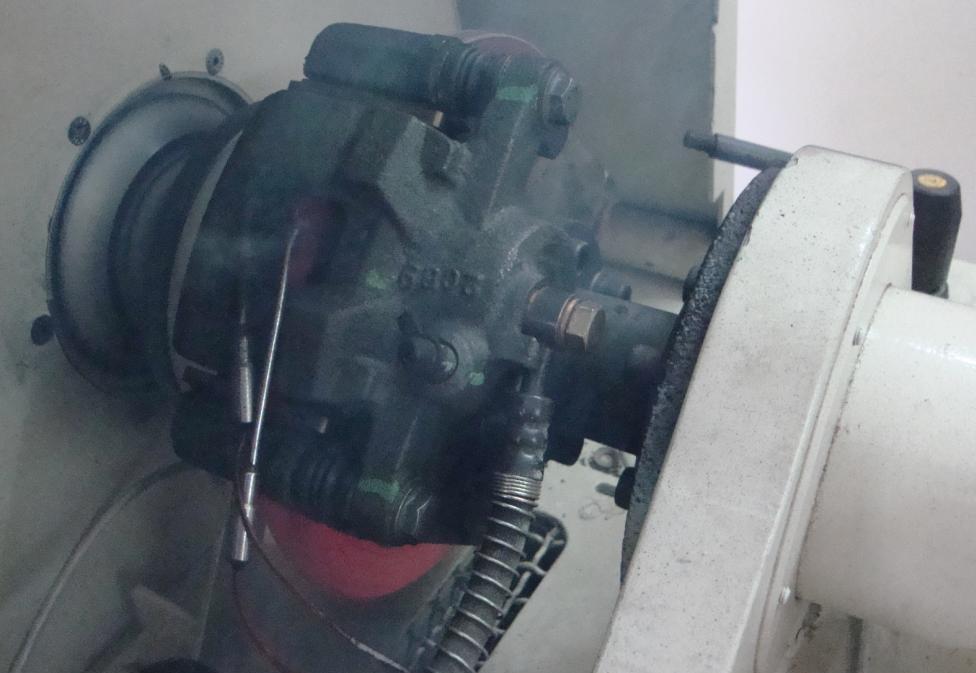

Krauss Test- ECE-R90

DYNAMIC DRAG @ 950 Deg. F

Pad with PG-902 Additive